Title

EXPERT CONTRACT MANUFACTURING SERVICES

Title

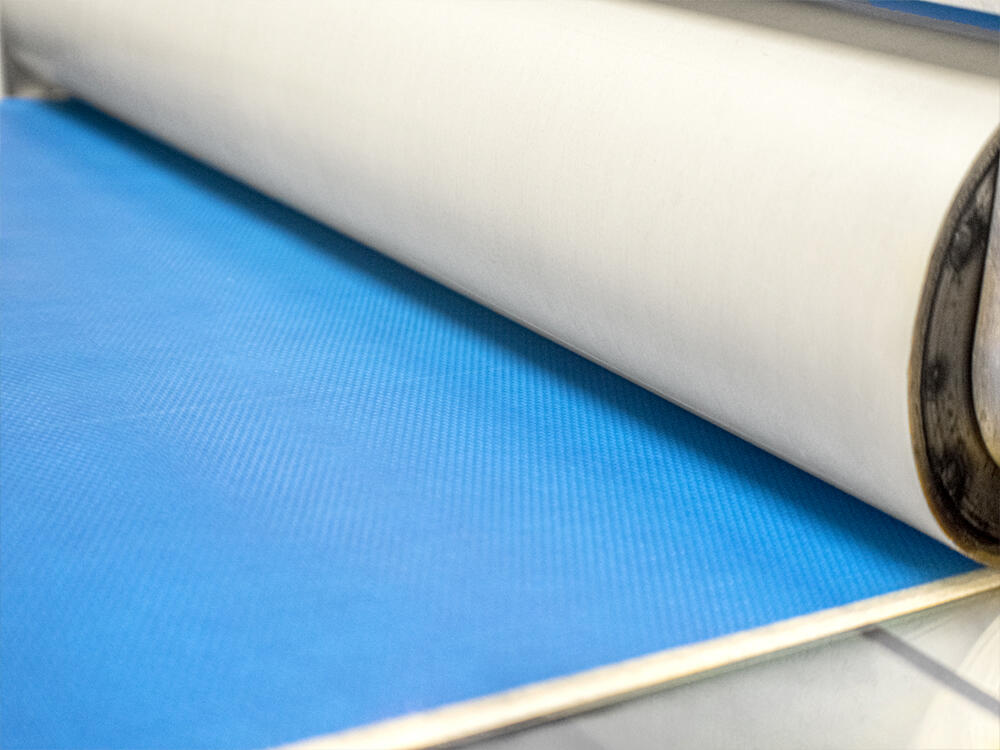

ADVANCED COATING AND LAMINATION FOR MEDICAL DEVICES

Title

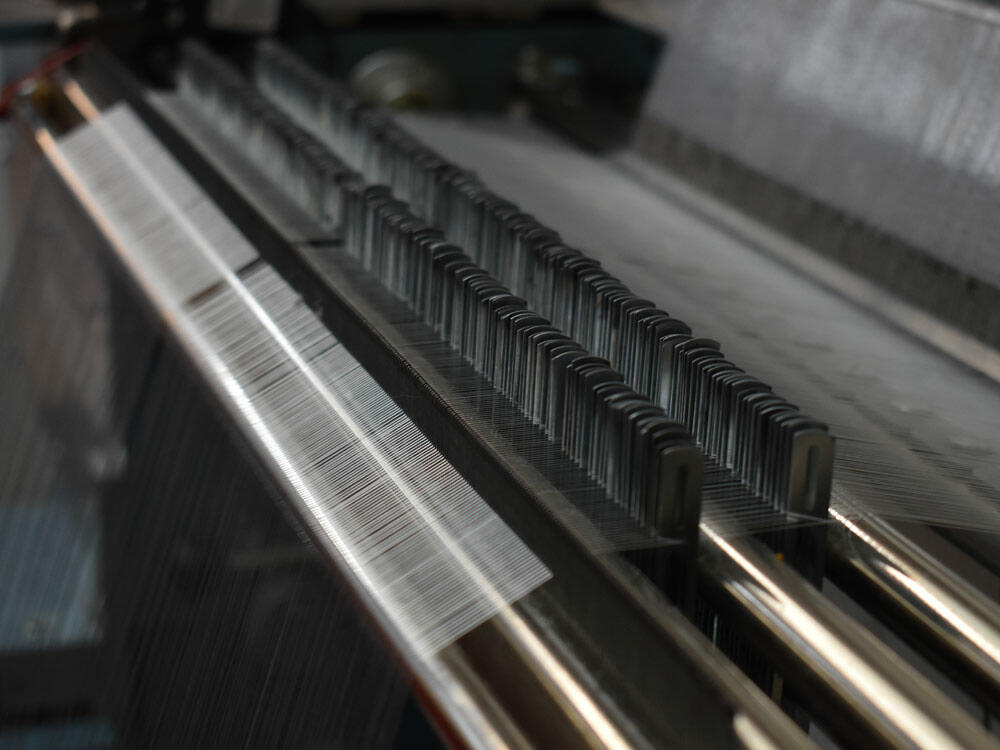

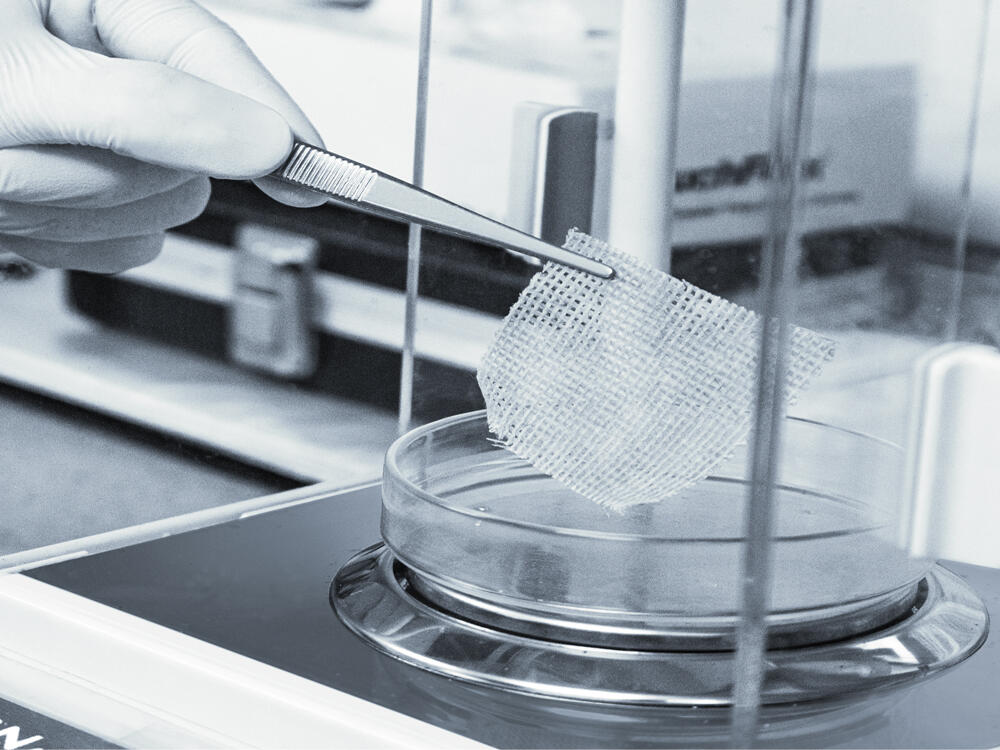

PRECISION TEXTILE MANUFACTURING

Title

PRECISION CUTTING AND SLITTING

Title

CUT AND SEW

Title

RF WELDING

Title

CONVERTING AND ASSEMBLY

Title

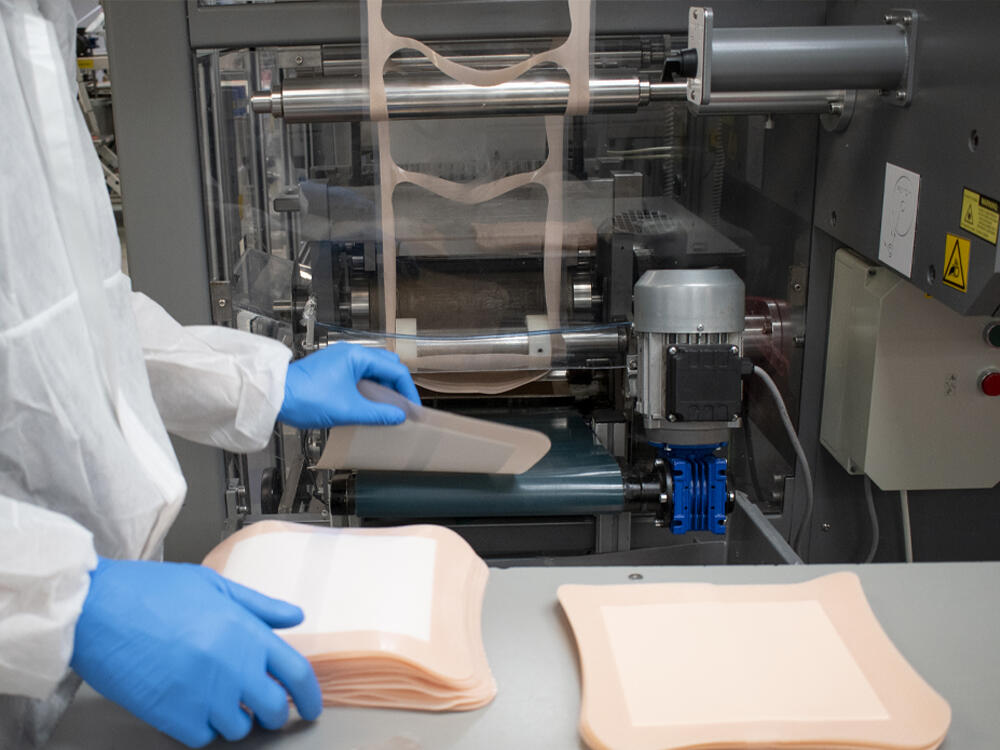

MEDICAL DEVICE ASSEMBLY

Title

FORMULATION, FILL AND FINISH

Title

PACKAGING

Title

LABORATORY AND MICROBIOLOGY TESTING

Title